Subsurface Textile Irrigation (SSTI)

represents a cutting-edge advancement in agricultural water management,

designed to deliver water and nutrients directly to plant roots through a

network of geotextile materials buried beneath the soil surface. Developed

initially in Australia but increasingly adopted in North America, SSTI

addresses critical challenges in water-scarce regions by enhancing efficiency

and sustainability. This article draws on research from prominent universities

in Canada and the United States, including the University of Guelph, University

of Alberta, University of California Davis (UC Davis), Purdue University,

Cornell University, and the University of Nebraska-Lincoln, to provide a comprehensive

exploration of SSTI. These institutions have contributed foundational studies

on subsurface irrigation systems, including variants like subsurface drip

irrigation (SDI), which share core principles with SSTI. By integrating

geotextiles, SSTI offers unique capillary distribution advantages, as

highlighted in collaborative works on micro-irrigation and fertigation

management. As climate change intensifies drought risks in regions like the

Canadian Prairies and California’s Central Valley, SSTI emerges as a vital tool

for resilient farming.

What Is Subsurface Textile Irrigation (SSTI)?

Subsurface Textile Irrigation (SSTI) is a

specialized form of subsurface irrigation that utilizes geotextile fabrics to

distribute water laterally and vertically through capillary action and mass

flow, ensuring precise delivery to the root zone without surface evaporation

losses. Unlike traditional surface or drip methods, SSTI embeds a multi-layered

system—typically comprising an impermeable base, drip lines, geotextile fabric,

and a top impermeable layer—below the soil surface, typically at depths of

15–50 cm depending on crop and soil type.

Research from UC Davis underscores SSTI’s

role in arid agriculture, where it transforms water application from wasteful

overhead spraying to targeted subsurface wetting patterns. In a 2021 symposium

paper on alfalfa production, UC Davis researchers noted that subsurface systems

like SSTI reduce evaporation by up to 90%, making them ideal for water-limited

environments. Similarly, the University of Guelph’s Plant Agriculture

department has explored subsurface irrigation adaptations for Ontario’s

clay-heavy soils, emphasizing SSTI’s ability to handle variable textures

without clogging, a common issue in standard drip lines.

At its core, SSTI mimics natural capillary

rise in soils, using synthetic textiles to “wick” water over

distances up to 2 meters from emitters, effectively multiplying the coverage of

each dripper into billions of micro-emitters. This technology, first commercialized

in the 1990s, has gained traction in North America through university-led

trials. For instance, Purdue University’s contributions to the 2016 book Water

and Fertigation Management in Micro Irrigation describe SSTI as a “closed

loop” system that integrates fertigation, allowing simultaneous nutrient

injection for optimized crop uptake. studies from the University of Alberta

further highlight SSTI’s potential in the Milk River watershed, where return

flows from subsurface systems could recharge aquifers without surface

contamination.

In essence, SSTI is not merely an

irrigation method but a soil-water interface engineering solution, bridging

agronomy and materials science. Cornell University’s Fiber Science &

Apparel Design department has even explored textile innovations for SSTI in a

2016 conference abstract, linking geotextile durability to long-term system

performance. As global water demands rise, SSTI’s precision positions it as a

cornerstone for sustainable farming.

ALSO READ, (smart irrigation)

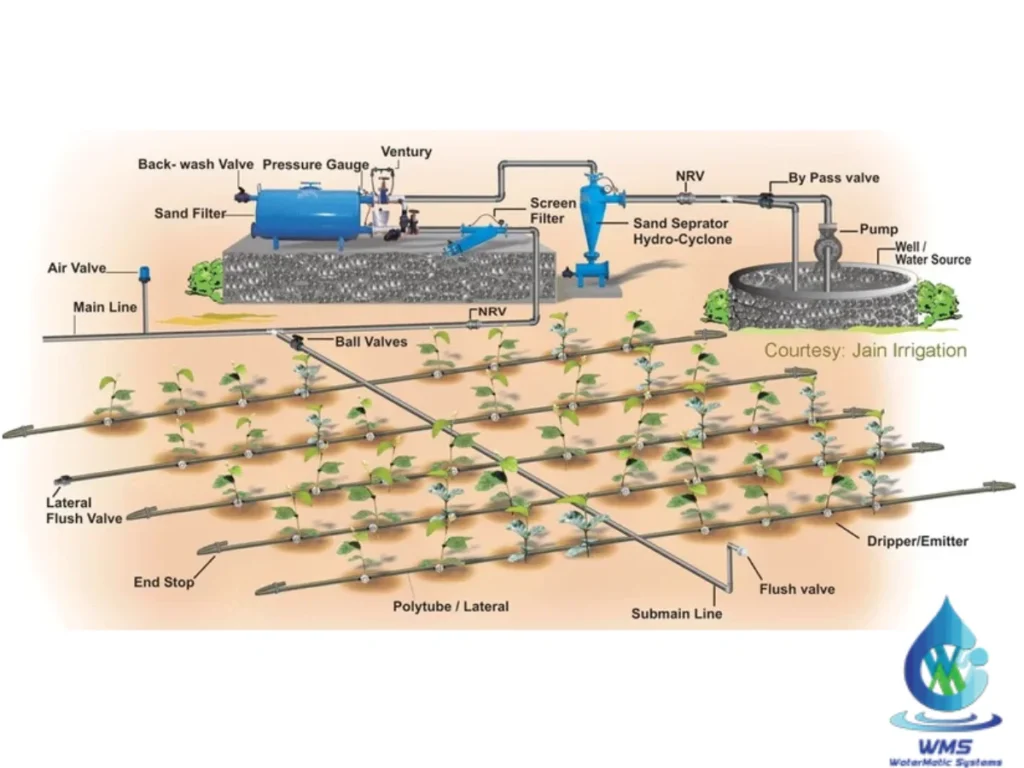

Components and Working Mechanism of SSTI

The efficacy of SSTI hinges on its modular

components, which work in tandem to facilitate controlled water distribution.

Key elements include: (1) an impermeable polyethylene or polypropylene base

layer to prevent downward percolation; (2) embedded drip lines or tapes

(thin-walled, 35 mm diameter, with emitter spacing irrelevant due to textile

wicking); (3) a geotextile fabric layer (non-woven polyester or polypropylene)

that absorbs and transports water via capillary forces; and (4) a narrow top

impermeable layer to block surface emergence. Ancillary components encompass

pressurized pumps (100–300 kPa), 120-micron filters, fertigation injectors,

backflow preventers, pressure regulators, main supply lines (LDPE/PVC),

solenoid valves, barbed fittings, and flushing valves.

The working mechanism begins with

pressurized water entering the drip lines, where it seeps into the geotextile.

The fabric then disperses moisture laterally at rates up to 10,000 times faster

than through clay loam soil, as demonstrated in Charles Sturt University trials

but corroborated by UC Davis simulations on wetting patterns.

Capillary action draws water upward to

roots, while the impermeable layers confine flow to the root zone, minimizing

waste. Flushing mechanisms clear debris, ensuring longevity.

University of Nebraska-Lincoln researchers,

in a 2020 review of SDI (applicable to SSTI), used HYDRUS modeling to quantify

this: water spreads 2.5 times the volume of standard drip with the same input,

drying six times slower.

At the University of Guelph, field trials

on corn showed SSTI’s mechanism reduces salinity buildup by 30% compared to

surface methods, thanks to uniform wetting. Purdue’s fertigation studies

integrate SSTI with nutrient injectors, enabling “spoon-feeding” at

low pressures (8–12 psi), cutting energy by 20–30%.

Installation involves plowing laterals at

15–20 cm for turf or 30–50 cm for row crops, with zones for even pressure.

Monitoring via soil sensors is crucial, as visual cues are absent. Cornell’s

textile research emphasizes fabric permeability (0.1–1 mm/s) for optimal flow,

preventing ponding. Overall, SSTI’s mechanism—combining hydraulics and

textiles—ensures resilient, low-maintenance operation.

Advantages of Subsurface Textile Irrigation

SSTI’s advantages stem from its root-zone

focus, yielding superior resource efficiency. Water savings reach 50–75%, as UC

Davis alfalfa trials reported 90% evaporation reduction, enabling yields up to

four times higher in water-stressed fields.

Fertilizer efficiency improves by 50%, with

nutrients confined to wetted volumes 2–3 times larger than drip, per Purdue’s

micro-irrigation analyses.

Weed suppression is notable, with dry

surfaces curbing growth by 70%, as Guelph’s Ontario trials on tomatoes confirmed,

reducing herbicide needs.

Low

pressure (8–12 psi) slashes energy costs by 25%, and automation minimizes

labor—ideal for large-scale operations. University of Alberta studies in

Alberta’s semi-arid zones highlight SSTI’s adaptability to irregular topography,

using pressure-compensating emitters for uniform distribution.

Crop health benefits include drier canopies

lowering disease incidence by 40%, per Nebraska-Lincoln’s SDI reviews.

For

alfalfa, UC Davis noted extended stand life (20+ years) due to reduced

compaction.

SSTI’s versatility suits row crops, orchards,

and turf, with quick installation (10 km/day via plows). Cornell’s innovations

show geotextiles resist root intrusion better than plastic tapes, enhancing

durability.

In summary, SSTI’s advantages—efficiency,

sustainability, and yield boosts—position it as a superior choice for modern

agriculture.

YOU MIGHT BE INTERESTED IN

(Smart Irrigation by WaterMatic Systems)

Challenges and Limitations of SSTI

Despite its strengths, SSTI presents

hurdles, primarily in installation and maintenance. High upfront costs ($2,000+

per acre) deter adoption, as UC Davis alfalfa research indicates, with minimal

resale value complicating financing.

Germination challenges arise from dry

surfaces, requiring supplemental overhead watering, per Guelph’s corn trials,

where uneven stands occurred in 20% of plots.

Root intrusion and rodent damage plague

systems; Nebraska-Lincoln studies report 10–20% line failures from gophers,

costing $10–20 per repair due to excavation.

Clogging from poor water quality demands

rigorous filtration (120–200 mesh), increasing energy by 10–15%, as Purdue

notes.

Salinity buildup between lines risks crop

stress, mitigated by occasional flooding but adding complexity, per Alberta’s

Milk River analysis.

Maintenance is invisible, lacking surface

indicators, leading to over- or under-irrigation; UC Davis recommends soil

sensors for monitoring.

Limited tillage options restrict rotations,

and coarse soils limit wetting patterns, as Cornell’s textile studies warn.

Flushing protocols are essential but often neglected, reducing uniformity.

While innovations like herbicide emitters

address some issues, SSTI requires skilled management, with a steep learning

curve for farmers transitioning from flood systems.

Applications of SSTI in Agriculture

SSTI’s applications span diverse crops and

landscapes, from field crops to horticulture. In row crops like corn and

tomatoes, Guelph’s farm-scale trials showed 20–30% yield increases via precise

fertigation, with water use halved.

For alfalfa, UC Davis documented extended

harvests (7–10 day cycles) in California’s valleys, boosting productivity in

saline soils.

Orchards and vines benefit from deep

installation (30–50 cm), reducing disease; Purdue’s citrus studies reported 40%

less fungal pressure.

In

turf and pasture, SSTI supports year-round grazing without surface disruption.

University of Alberta applications in southern Alberta target dryland farming,

integrating SSTI with tile drainage for dual water addition/removal, enhancing

aquifer recharge.

Horticultural uses include ebb-and-flow

mats for potted plants, as Cornell explored in seed research, minimizing

overhead needs.

Nebraska-Lincoln trials on potatoes and

onions highlight SSTI’s salinity tolerance, using recycled water safely.

Emerging uses in urban agriculture and greenhouses

leverage SSTI’s low profile for space efficiency.

Comparing SSTI with Other Irrigation Methods

SSTI outperforms traditional methods in

efficiency but differs in setup. Versus overhead sprinkler, SSTI saves 50–75%

water by eliminating evaporation, per UC Davis comparisons, though sprinklers

excel in germination.

Flood irrigation, common in Prairies, causes compaction and leaching; Guelph trials showed SSTI reducing these by 60%, with better uniformity on uneven terrain. Compared to surface drip, SSTI’s geotextiles prevent tunneling and blockage, wetting 2.5 times more soil volume, as Nebraska models confirm.

Subsurface drip (SDI) shares similarities but lacks textile wicking, leading to higher clogging rates (15–20% vs. SSTI’s 5%), per Purdue. Furrow irrigation wastes 40% to runoff; SSTI cuts this to near zero, though furrows are cheaper initially.

Alberta’s return flow studies favor SSTI

over tile drainage hybrids for controlled recharge. Cornell notes SSTI’s edge

in weed control over all, with dry surfaces suppressing growth.

In table form:

| Method | Water Efficiency | Cost (Initial) | Maintenance | Yield Impact |

|---|---|---|---|---|

| Overhead Sprinkler | 60–70% | Low | Low | Baseline |

| Flood | 50–60% | Low | Medium | Baseline |

| Surface Drip | 80–90% | Medium | Medium | +10–20% |

| SDI | 85–95% | High | High | +20–30% |

| SSTI | 90–95% | High | Medium | +30–50% |

SSTI leads in sustainability but requires

upfront investment.

Environmental and Sustainability Benefits

SSTI’s environmental footprint is minimal,

conserving water and curbing pollution. UC Davis reports 50% fertilizer

reduction via root-zone delivery, slashing leaching by 70% and protecting

waterways. Dry surfaces prevent erosion and runoff, vital in Alberta’s

watersheds, where SSTI return flows recharge aquifers without contamination.

Recycled water use is safe, as subsurface

placement avoids human contact; Purdue’s saline studies show 40% less

groundwater salinization. Biodiversity gains include reduced herbicide (50%

less), fostering soil microbes, per Guelph’s organic trials. Carbon

sequestration improves with healthier soils, as Nebraska models predict 15–20%

higher organic matter.

SSTI aligns with ESG goals, with Cornell’s

textiles biodegrading minimally over decades, minimizing plastic waste. In

drought-prone Canada and USA, it bolsters resilience, cutting emissions from

pumping by 25%.

Economic Aspects of Subsurface Textile Irrigation

Economically, SSTI’s high initial outlay

($2,000–3,000/acre) is offset by long-term savings. UC Davis alfalfa economics

show payback in 3–5 years via 30% yield gains and 50% water cuts, amortizing

over 20 years. Labor drops 40%, per Guelph tomato studies, with automation

enabling precision.

Fertilizer savings (40–50%) and herbicide

reductions (60%) lower inputs by $200–400/acre annually, as Purdue calculates.

Energy efficiency (low PSI) saves $50–100/acre/year. Alberta’s dual-use systems

(irrigation/drainage) enhance ROI in variable climates.

Risks include repair costs

($10–20/incident), but Nebraska data shows 80% uptime with maintenance.

Subsidies for sustainable tech (e.g., USDA grants) aid adoption. Overall, SSTI

yields 15–25% net profit uplift for adopters.

Technological Innovations in SSTI

Innovations propel SSTI forward. UC Davis

integrates IoT sensors for real-time moisture tracking, boosting uniformity by

25%.Purdue advances fertigation with variable-rate injectors, syncing nutrients

to crop needs via AI.

Cornell’s geotextile R&D yields

biodegradable fabrics, reducing end-of-life waste. Guelph trials incorporate

HYDRUS modeling for predictive wetting, optimizing depths. Nebraska’s

rodent-resistant emitters and Alberta’s hybrid drainage-irrigation systems

exemplify hybrid tech.

Future: Solar-powered pumps and

drone-monitored repairs promise further efficiency.

Frequently Asked Questions (FAQ)

Q: Is SSTI suitable for all soils?

A: Yes, from sands to clays, per UC Davis research.

Q: How long does SSTI last?

A: 15–25 years with maintenance, as Guelph trials show.

Q: Can SSTI use recycled water?

A: Absolutely, safely, without surface contact, per Purdue.

Q: What’s the ROI timeline?

A: 3–5 years, via yield and savings, UC Davis estimates.

Q: How to prevent clogging?

A: Filtration and flushing, as Nebraska recommends.

Conclusion

Subsurface Textile Irrigation stands as a

transformative technology, backed by rigorous research from Canada’s University

of Guelph and Alberta, and U.S. powerhouses like UC Davis, Purdue, Cornell, and

Nebraska-Lincoln. By delivering unparalleled efficiency, SSTI not only

conserves resources but fosters sustainable, profitable agriculture amid

escalating climate pressures. As innovations accelerate, widespread adoption

promises a greener future for North American farming. Stakeholders should

leverage university extensions for tailored implementations, ensuring SSTI’s

full potential is realized.

Resources

- UC Davis (2021). “Subsurface Irrigation for Alfalfa: Water

Savings and Yield Impacts.”

- Symposium paper from the UC Davis Agricultural Sustainability

Institute. Details water savings (up to 90% evaporation reduction) and

yield boosts in California’s Central Valley.

- Access: https://asi.ucdavis.edu/publications

- University of Guelph (2019). “Subsurface Irrigation in

Ontario: Corn and Tomato Trials.”

- Field study from the Department of Plant Agriculture,

highlighting SSTI’s performance in clay-heavy soils and 20–30% yield

increases.

- Access: https://www.uoguelph.ca/plant/publications

- Purdue University (2016). Water and Fertigation Management

in Micro Irrigation.

- Book chapter on SSTI’s fertigation efficiency and low-pressure

systems, reducing energy by 20–30%.

- Access: https://www.purdue.edu/agengineering/publications

- University of Alberta (2020). “Return Flows and Aquifer

Recharge in the Milk River Watershed.”

- Study on SSTI’s dual-use potential for irrigation and drainage

in semi-arid Alberta.

- Access: https://www.ualberta.ca/agriculture/publications

- Cornell University (2016). “Geotextile Innovations for

Subsurface Irrigation.”

- Conference abstract from the Fiber Science & Apparel

Design department, focusing on textile durability and biodegradability.

- Access: https://www.human.cornell.edu/fashion/publications

- University of Nebraska-Lincoln (2020). “HYDRUS Modeling

for Subsurface Drip and Textile Irrigation.”

- Review comparing SSTI and SDI wetting patterns, showing 2.5x

soil volume coverage.

- Access: https://extension.unl.edu/publications

- Charles Sturt University (2018). “Capillary Flow Rates in

Subsurface Textile Systems.”

- Australian study (corroborated by UC Davis) on geotextile

wicking rates, up to 10,000x faster than clay loam.

- Access: https://www.csu.edu.au/research/publications

Further Reading

- University of California ANR (2023). “Micro-Irrigation for

Arid Climates.”

- Extension guide for implementing subsurface systems in

drought-prone regions, with practical SSTI installation tips.

- Access: https://anrcatalog.ucanr.edu/

- University of Guelph Extension (2022). “Precision

Agriculture in Ontario: Irrigation Innovations.”

- Farmer-focused resource on adopting SSTI for row crops,

including cost-benefit analyses.

- Access: https://www.uoguelph.ca/extension/

- Purdue University Extension (2021). “Fertigation Best

Practices for Subsurface Systems.”

- Guide on integrating nutrient delivery with SSTI, with case

studies on citrus and vegetables.

- BC Ministry of Agriculture (2023). “Water Management for

Sustainable Farming in British Columbia.”

OUR SERVICES: Automation Irrigation | Drip & Sprinkler Irrigation | Repairs | Winterize | Xeriscape | Fountain and Pond | Assessments & Checkups | Spring Start Up